Accelerate Decarbonization Initiatives & Save up to 30% on Energy Bills

Track, Monitor and Control Energy Inefficiencies & Wastages. Energy Savings with ML & AI-led Automation & Policy-based Control.

Get rid of HVAC System Inefficiencies

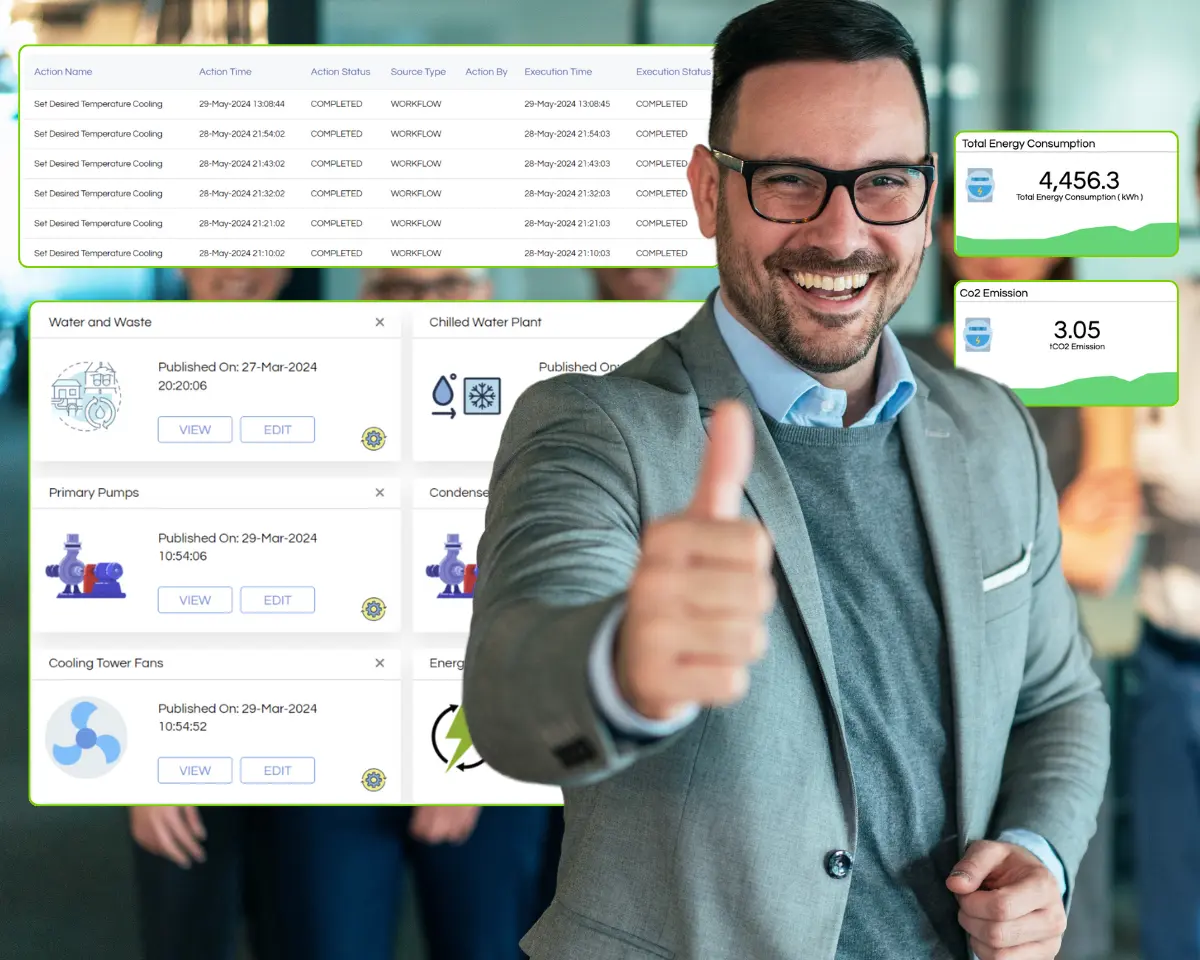

Reduce Energy Wastage related to improper HVAC commissioning, Chiller sequencing & Valve controls. Modulate the HVAC system autonomously

Deploy Energy Conservation Measures

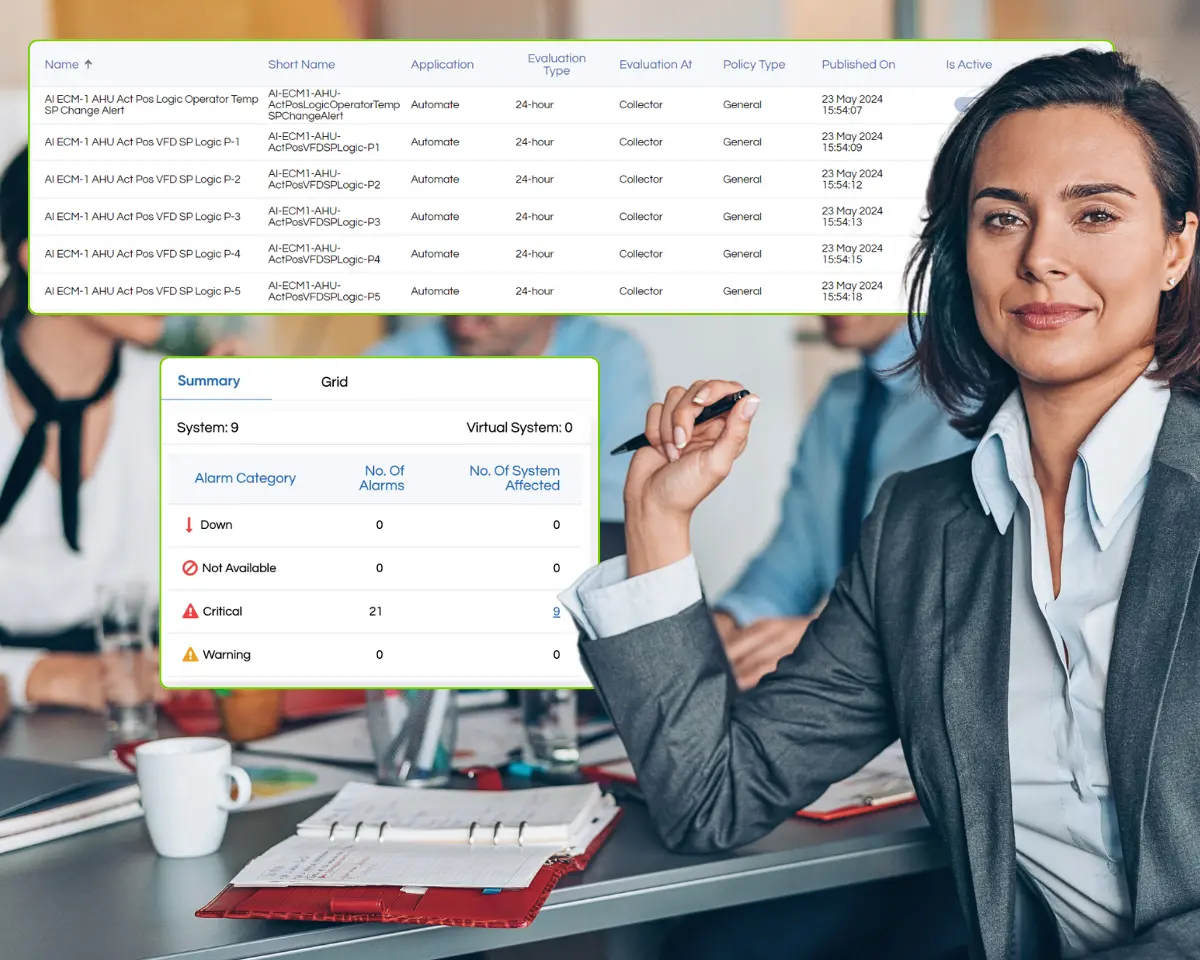

Baseline Energy Intensity & use advanced Fault Detection & Diagnosis (FDD) algorithms along with Energy Conservation Measures (ECM) to optimize Chiller & AHU operations

ML & AI Algorithms to Save Energy

ML & AI Algorithms for early anomaly detections & autonomous corrections. Forecast energy and thermal demand to optimize energy usage

Reduce Carbon Footprint & Decarbonize

Measure & report Carbon Footprint along with other ESG metrics. Accelerate Decarbonization to meet your Sustainability goals

Get rid of HVAC System Inefficiencies

- HVAC System audit to Identify & Correct commissioning errors

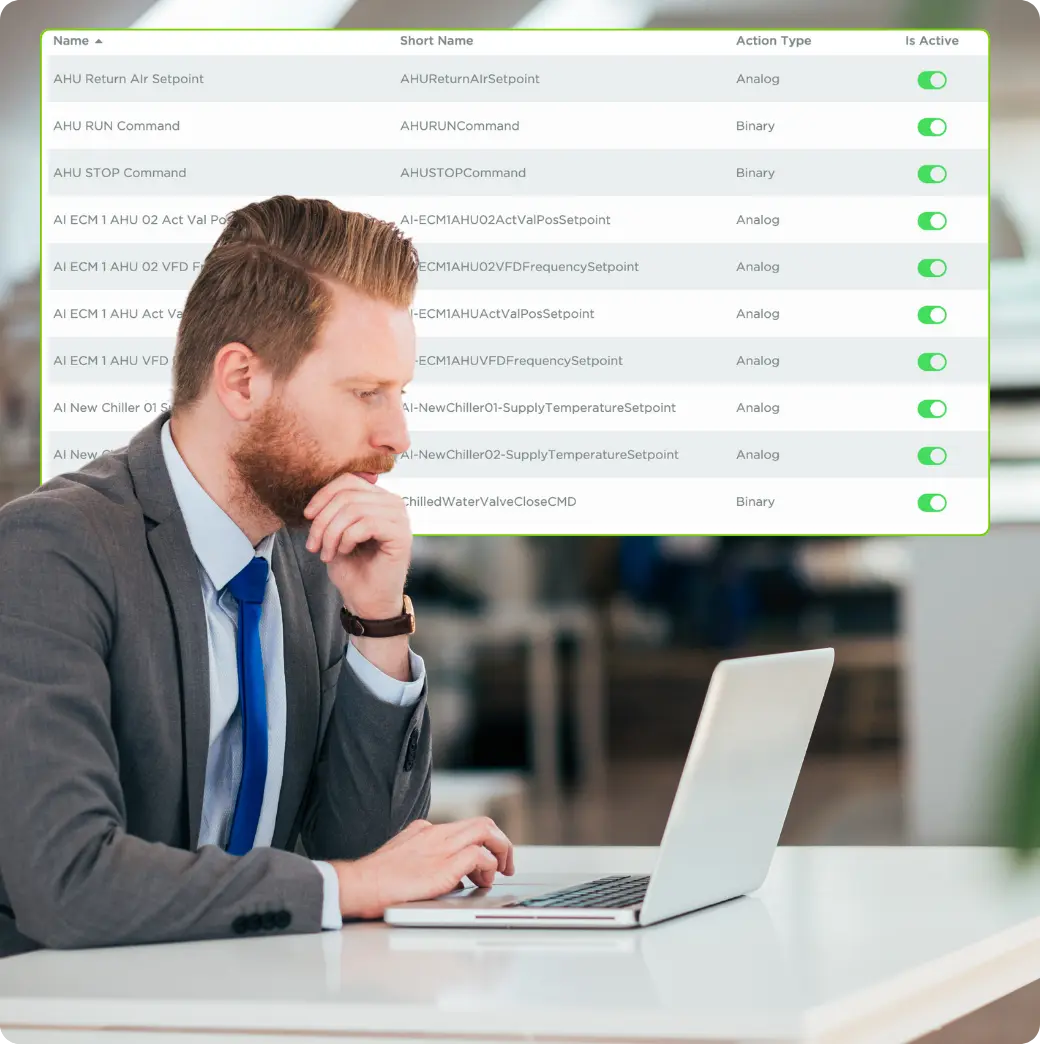

- Analyse system operational data for optimization of control logic

- Modulate the HVAC system autonomously to meet comfort demand

Implement Energy Conservation Measures

- Establish Energy baseline

- Correct HVAC operational issues through advanced Fault Detection & Diagnosis (FDD) rule

- ECMs to optimize chiller and AHU operations towards Energy Savings

- Energy Use Intensity (EUI) normalization to remove the variances due to area, weather, occupancy, production etc.

ML & AI Algorithms to Save Energy

- Detect anomalies through proprietary ML & AI algorithms to provide visibility for early corrections

- Forecast zone-wise energy & thermal characteristics

- Initiate autonomous control to optimize energy basis zone-wise forecast

- Control HVAC to help reduce energy without losing the comfort of the employees

Reduce Carbon Footprint, Decarbonize Faster

- Track energy consumption and energy savings

- Monitor consumption, leakage & recycling of water, waste, emissions and environmental parameters

- Continuous commissioning of the HVAC control system to prevent faults, schedule maintenance

- ESG Compliance Report including Energy, Water, Waste, Environment & Emission (Scope 1 & 2)

Common Reasons for Energy Wastage

HVAC Inefficacy

Chiller sequencing valve controls, equipment health, improper design, deficiency of controls etc. cause significant energy wastage

No Energy Focus

Lack of real-time Energy monitoring/ Energy conservation measures result in unknown energy leakages

Power Factor

Automatic Power Factor Correction (APFC) Panels are not managed or not connected to major load. Unmanaged power factor leads to high penalties

Manual Bypass

Operators change sequences or set points or bypass critical alarms resulting in energy wastage

Condition Monitoring

Absence of Pre-alerts for developing faults in Chillers/ Pumps/ Fans

External Weather

External weather impacts energy demand, allows pre-cooling/ pre-heating and is typically not considered for HVAC control

HVAC Scheduling

HVAC usage outside of office hours due to manual scheduling increases energy

Sensing Occupancy

HVAC control is typically not aligned with occupancy and comfort data

Sounds familiar?

How a Large Corporate Real Estate firm saved 20% on Energy Bills

2 buildings. | 1.4 Million Sq. Ft.

Challenges

- Manual & inefficient building operations

- Error prone Energy data audits

- Cumbersome ESG Reporting

- Lack of digitized Asset Management & Maintenance

Solutions

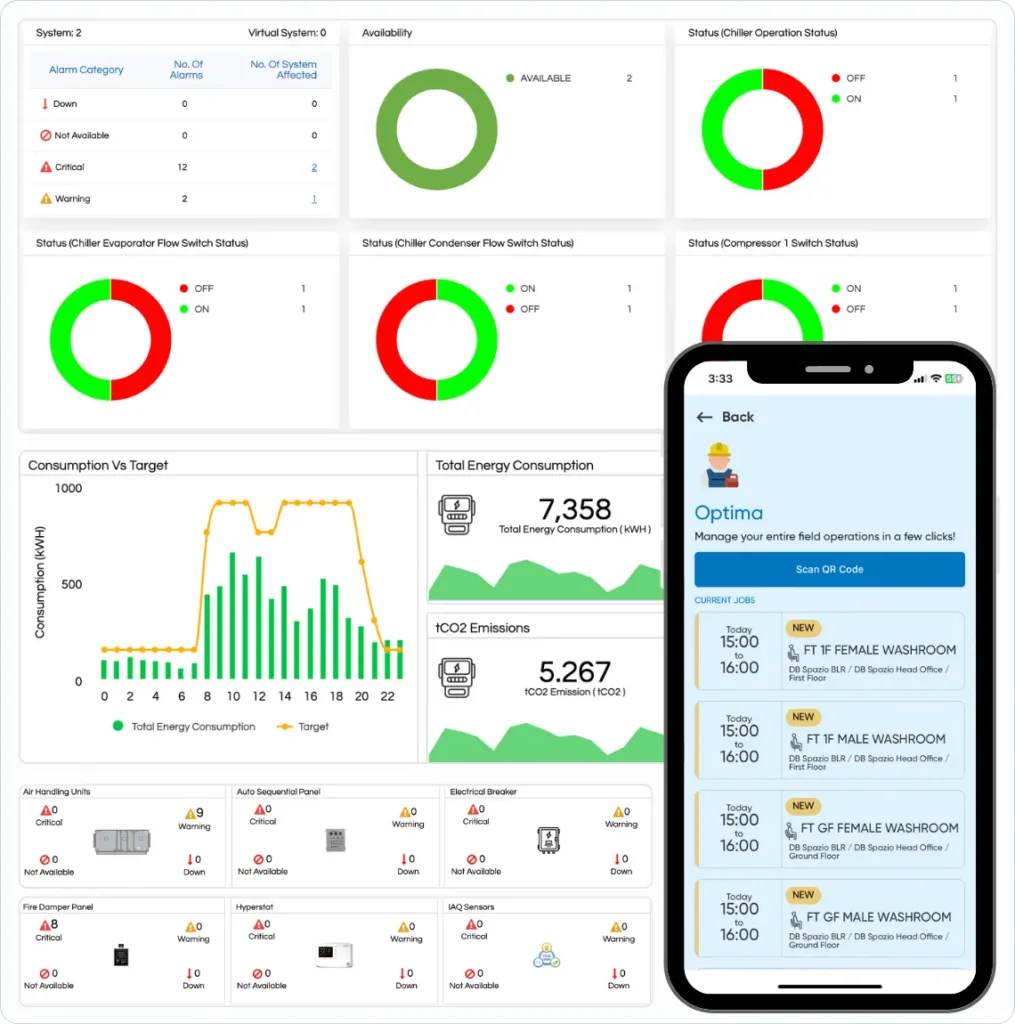

- Building Automation & Active Energy Management

- Asset Management and Planned Preventative Maintenance (PPM)

- Advanced FDD Algorithms

- HVAC System Audit, Demand Based Cooling

- Chiller Sequencing, VFD and CHW Valve Control

Outcomes

- 20% reduction in Energy Bills through automated modulation

- Faults detected in CPM, Flow Control, VFD Operation in addition to FAS

- ESG Compliance Report including Energy, Water, Waste, Environment & Emission

- Energy Reduction of INR 4 Lacs per month

- Savings on IBMS and CPM AMC’s

See it in action!

Explore Possibilities with db Energy at the center

Accelerate Sustainability goals and Compliance with our Building Automation Solution

- Automated AI engine led interventions to control HVAC set points, chiller management etc.

- Demand forecasting using past data, weather data, production planning, utility pricing, occupancy density etc.

- Report on sustainability, ESG and ASHRAE compliances

Simplify Operations & Maintenance with our CAFM/ CMMS Solution

- Automate ticket management and staff scheduling for Asset Management and Planned Preventative Maintenance (PPM)

- Assign relevant checklists and jobs to the field force based on faults & alerts

- Digitized Scope 3 reports from vendors through structured eForms without writing a line of code

Sense & Correlate Occupancy Patterns with Energy Consumption

- Real-time Floor-density tracking to manage comfort control

- Identify Ghost Bookings & Control HVAC/ lighting operations to save energy

Ready to explore? Get in touch with us to find out more

Solutions for Different Industry Segments

FAQs

DB Energy engine primarily consists of a neural network model, enhanced through another ensemble method to get the maximum benefit.

- The neural network model used in energi.ai is an LSTM (Long Short-Term Memory) model that is one of the best machine learning model types to learn from multivariate time-series data.

- The other model in use is an Autoencoder which is essentially driven to detect anomalies from the KPI data received.

- While both the above models improve over time as they learn from the specific environment they are deployed at, the Autoencoder improves significantly over time.

- The models mentioned above deliver the primary feed for the actions and itS further strengthened by the Ensemble Method used to improve the accuracy of the output.

- Essentially, EUI expresses a building’s energy use as a function of its size or other characteristics. EUI is expressed as energy per square foot per year. It’s calculated by dividing the total energy consumed by the building in one year by the total gross floor area of the building.

- Generally, a low EUI signifies good energy performance. However, certain property types will always use more energy than others.

- So, what really matters is the reduction of EUI and not the energy per se. Energy bills may vary based on changes in the unit cost. But EUI is a standard measure.

Energy Use Intensity (EUI) is normalized for weather, occupancy, production etc. and then used for performance benchmarking and comparison. Normalization removes the variances due to area, weather, occupancy, production etc.

- All controls can be bypassed manually like in any normal CPM or IBMS.

- Checkboxes on db Software enable/ disable any of these controls. This delinks the AI-generated class labels from the action control subsystem and therefore the AI-generated labels trigger no actions on the end devices.

- Triggering individual system controls from the console. The actions on the various subsystems can be performed from the console in a semi-automated mode.

GOT MORE QUESTIONS?

SEND US A MESSAGE! WE’RE HERE TO HELP.